Air Jet Mill

Dry-Type Milling Facility

Strengths of Miracle Solution’s Air Jet Mill Facility

Nano-Size Grinding Using Air

and N₂ as Grinding Media

Grinding Using Air

and N₂ as Grinding Media

Precise Particle Size Control

to accelerate materials, causing high-speed collisions that break

them down into nano-size particles.

This process allows for precise particle size and distribution control,

making it suitable for the production of fine particles across various industries.

A D50 value of 2μm means that the median particle size is 2μm,

indicating that the particles are extremely small and uniformly distributed.

Such optimization plays a crucial role in improving the quality

and productivity of secondary battery materials through efficient milling.

Therefore, facility enhancement and adjustments are essential

to maximize process efficiency and productivity.

Precise Particle Size Control

compressed gas to accelerate materials,

causing high-speed collisions that break them down

into nano-size particles.

This process allows for precise particle size

and distribution control, making it suitable

for the production of fine particles across various industries.

A D50 value of 2μm means that the median particle

size is 2μm, indicating that the particles are extremely small

and uniformly distributed

Such optimization plays a crucial role in improving

the quality and productivity of secondary battery materials

through efficient milling.

Therefore, facility enhancement and adjustments

are essential to maximize process efficiency and productivity

Precise Particle Size Control

N₂ involves high-pressure compressed

gas to accelerate materials,

causing high-speed collisions that break

them down into nano-size particles.

This process allows for precise particle size

and distribution control, making it suitable

for the production of fine particles across

various industries.

A D50 value of 2μm means that the median

particle size is 2μm, indicating

that the particles are extremely small

and uniformly distributed.

Such optimization plays a crucial role in

improving the quality and productivity

of secondary battery materials through

efficient milling.

Therefore, facility enhancement

and adjustments are essential

to maximize process efficiency

and productivity.

Strengths of Miracle Solution’s Air Jet Mill Facility

of Objects and Target Size

to Characteristics

of Objects and Target Size

Applications

including secondary batteries, chemicals, pharmaceuticals, biotechnology,

and food.

Ranging from large-scale industrial milling facilities to small-scale lab facilities for research purposes

Applications

various industries, including secondary batteries, chemicals,

pharmaceuticals, biotechnology, and food.

Ranging from large-scale industrial milling facilities

to small-scale lab facilities for research purposes.

Applications

and application-specific raw material

production across various industries, including

secondary batteries, chemicals,

pharmaceuticals, biotechnology, and food.

Ranging from large-scale industrial milling

facilities to small-scale lab facilities for

research purposes

Strengths of Miracle Solution’s Air Jet Mill Facility

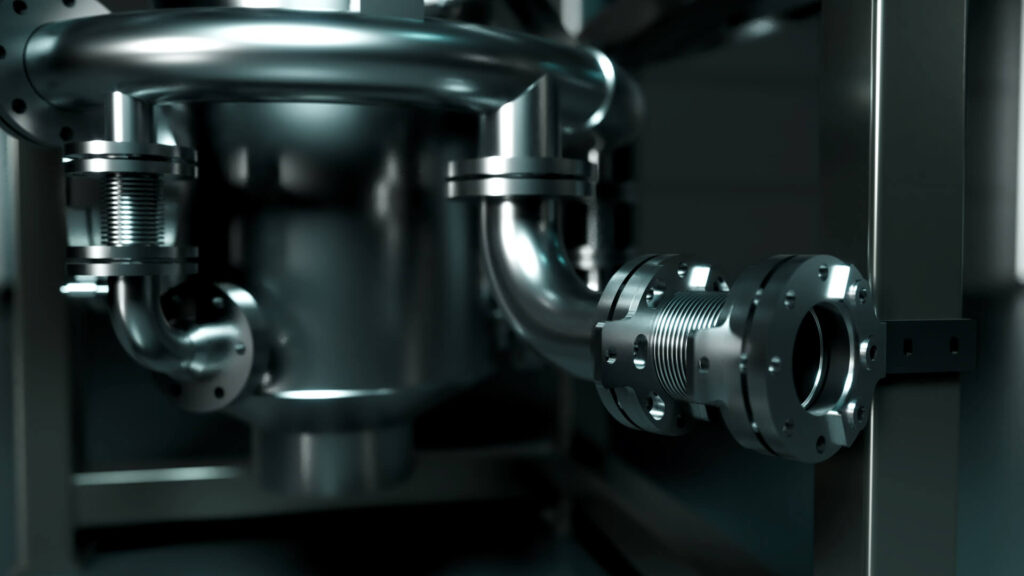

Contamination

All Parts Sealed to Prevent Powder Contamination

High-Efficiency Design

without the need for external tools or equipment.

Additionally, all the parts are sealed to prevent any powder or particles generated during milling from being released, minimizing powder

contamination.

These features enhance the efficiency of the milling process,

helping to maintain product quality and prevent contamination.

High-Efficiency Design

between particles without the need for external tools

or equipment.

Additionally, all the parts are sealed to prevent any powder

or particles generated during milling from being released,

minimizing powder contamination.

These features enhance the efficiency of the milling process,

helping to maintain product quality and prevent

contamination.

High-Efficiency Design

Additionally, all the parts are sealed to prevent

any powder or particles generated during

milling from being released, minimizing

powder contamination.

These features enhance the efficiency of the

milling process, helping to maintain product

quality and prevent contamination.

Strengths of Miracle Solution’s Air Jet Mill Facility

Flexible use for temperature-sensitive products

Flexible use for temperature-sensitive products

Key Features of Air Jet Mill

the process minimizes temperature rise during milling.

This allows for effective heat control during the milling process,

enabling stable handling of temperature-sensitive products.

Due to these characteristics, the Air Jet Mill is particularly suitable

for processing temperature-sensitive materials and is widely used

in the pharmaceutical and food industries.

Key Features of Air Jet Mill

the process minimizes temperature rise

during milling.

This allows for effective heat control during

the milling process, enabling stable handling

of temperature-sensitive products.

Due to these characteristics, the Air Jet Mill is

particularly suitable for processing

temperature-sensitive materials and is widely used

in the pharmaceutical and food industries.

Key Features of Air Jet Mill

By using ambient air as the grinding medium

the process minimizes temperature rise during

milling.

This allows for effective heat control during

the milling process, enabling stable handling

of temperature-sensitive products.

Due to these characteristics, the Air Jet Mill is

particularly suitable for processing

temperature-sensitive materials and is widely

used in the pharmaceutical and food industries.

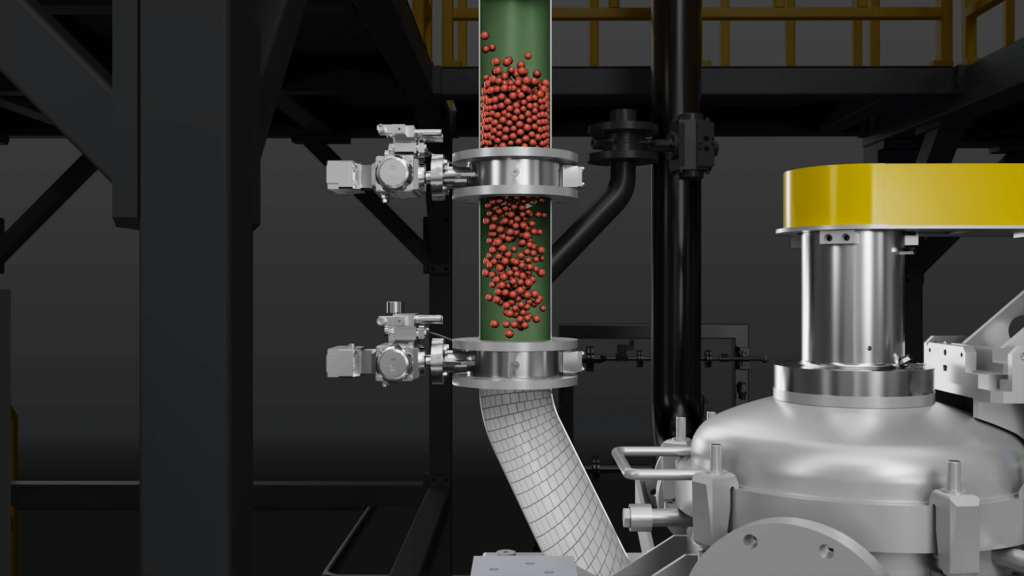

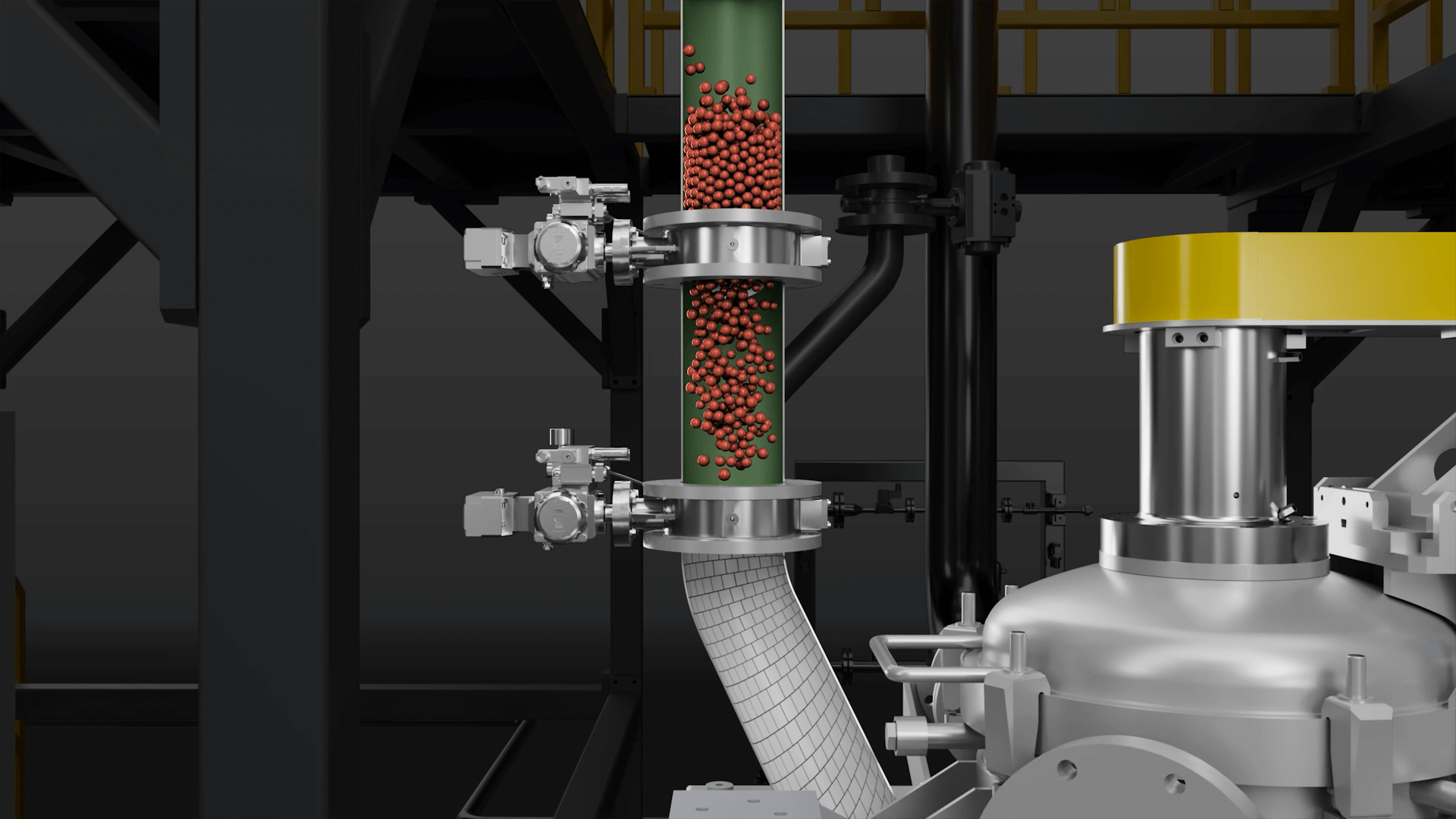

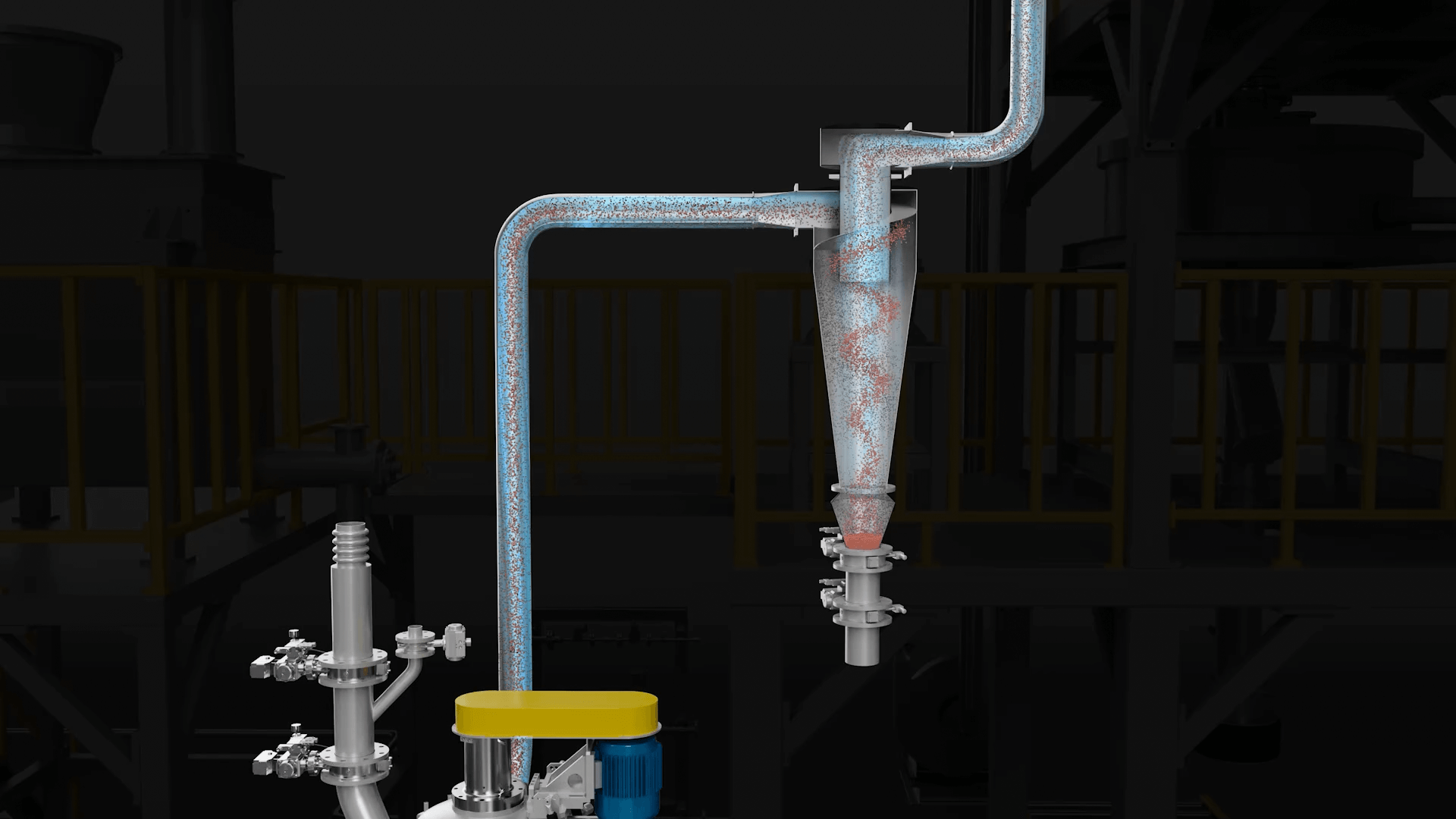

Milling Process of Air Jet Mill

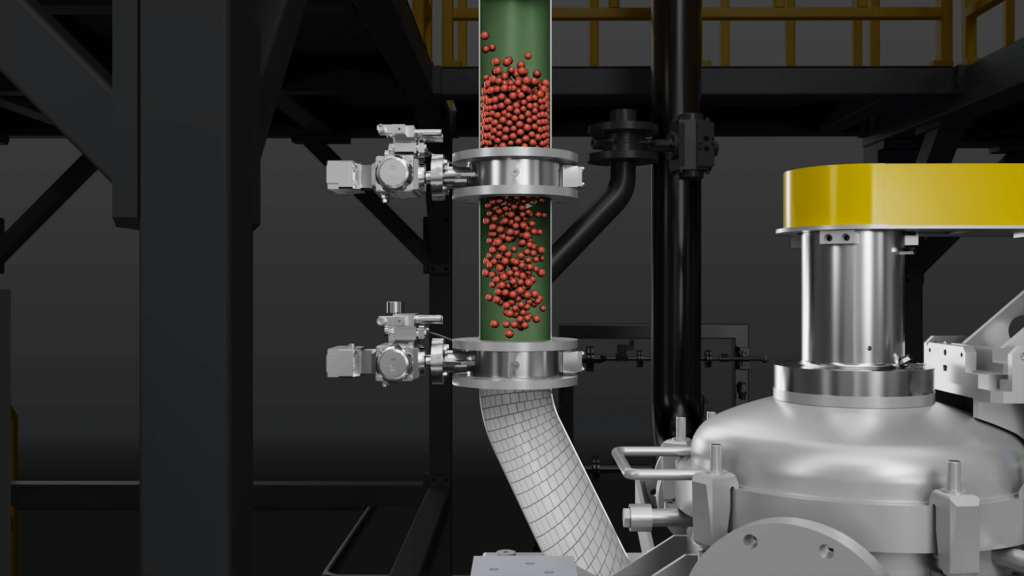

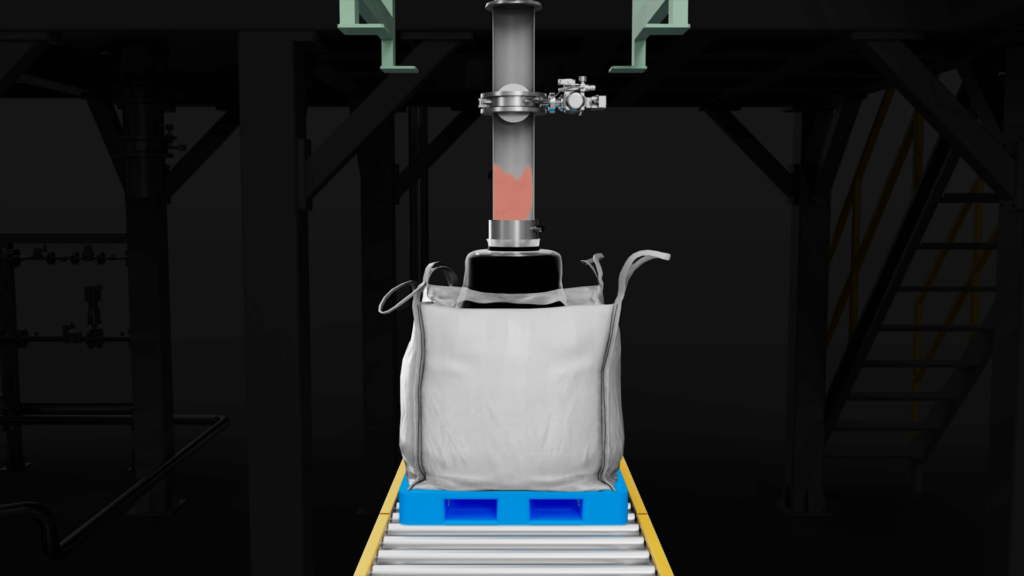

Raw Material Inlet

ㆍIntroduce the raw material into the Air Jet Mill chamber

ㆍPowerful air jets are released from three directional nozzles to achieve

the target particle size grinding

ㆍDuring the primary milling, large particles rise while smaller particles

are discharged at the bottom

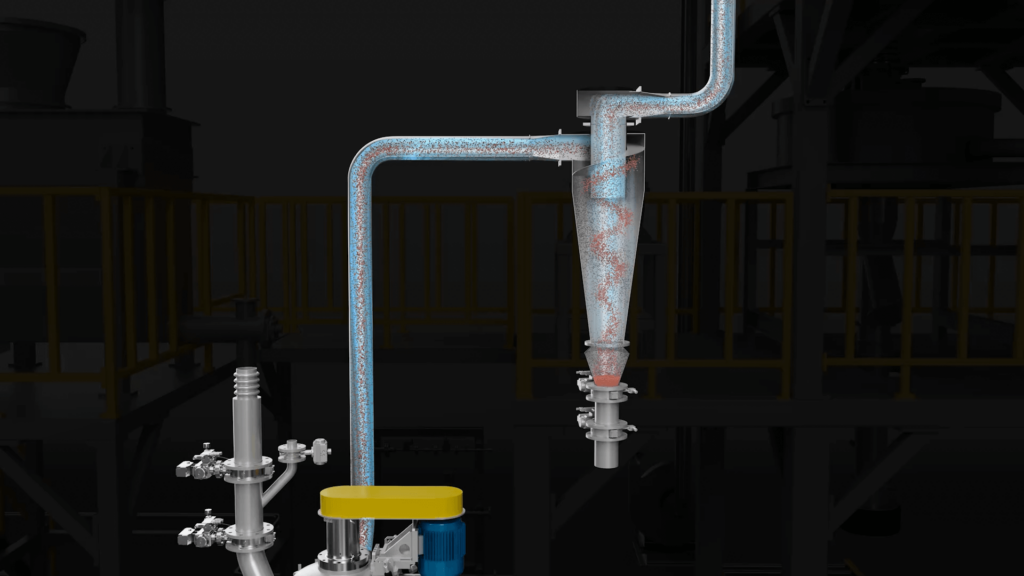

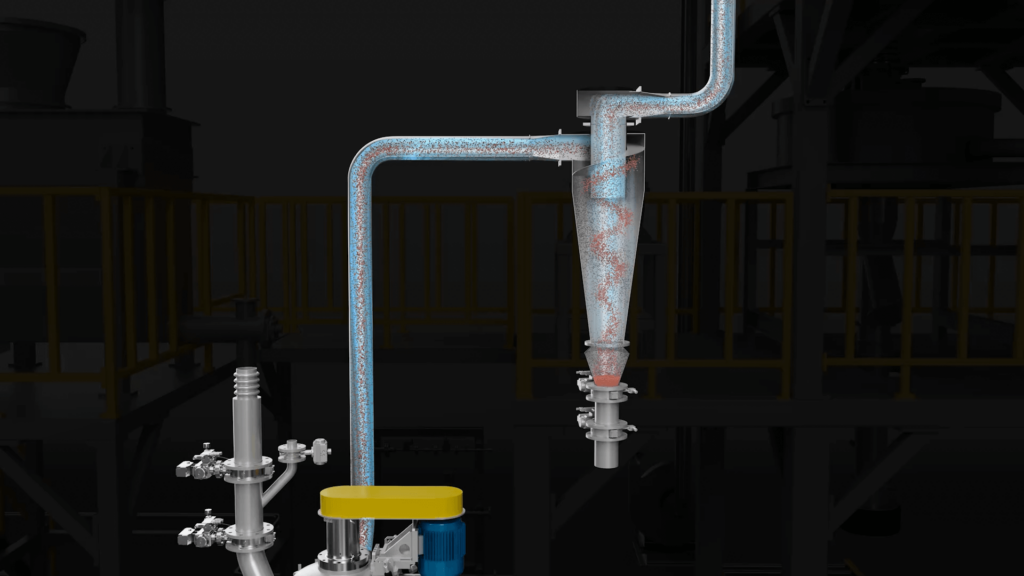

Cyclone

ㆍInside the cyclone, the airflow spirals like a vortex

ㆍHeavy and large particles move to the bottom,

while smaller particles follow the swirling airflow to the top

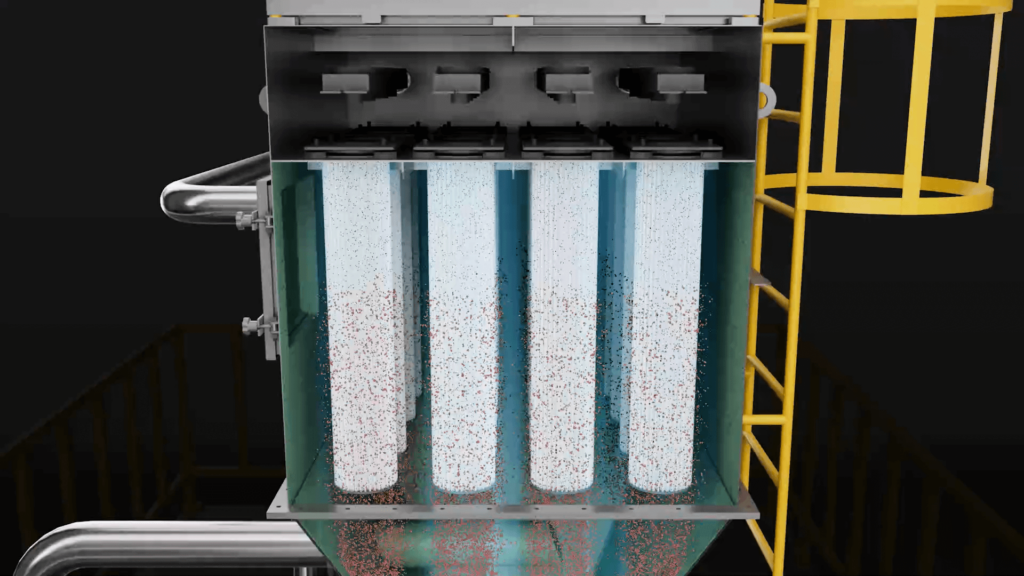

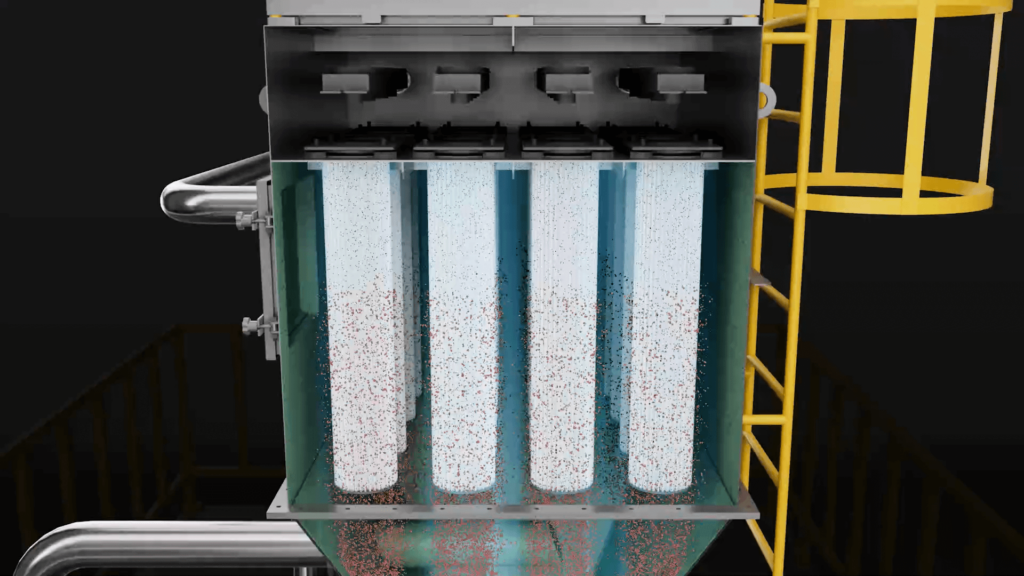

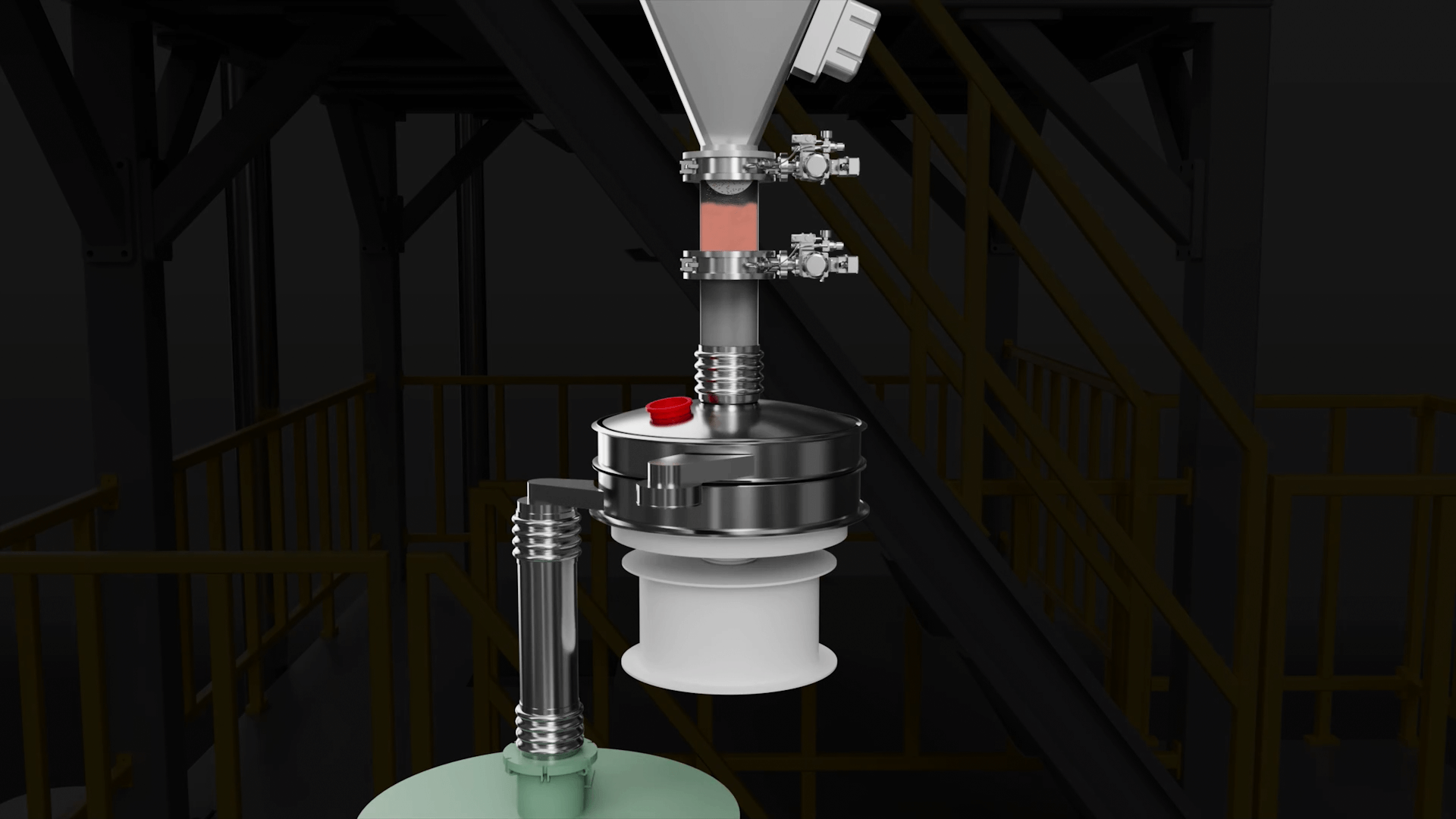

Bag Filter

ㆍThe milled raw material follows the airflow and adheres

to the surface of the bag filter

ㆍAir is momentarily released from the upper nozzle of the bag filter,

dislodging the adhered material on the filter

and directing it downward

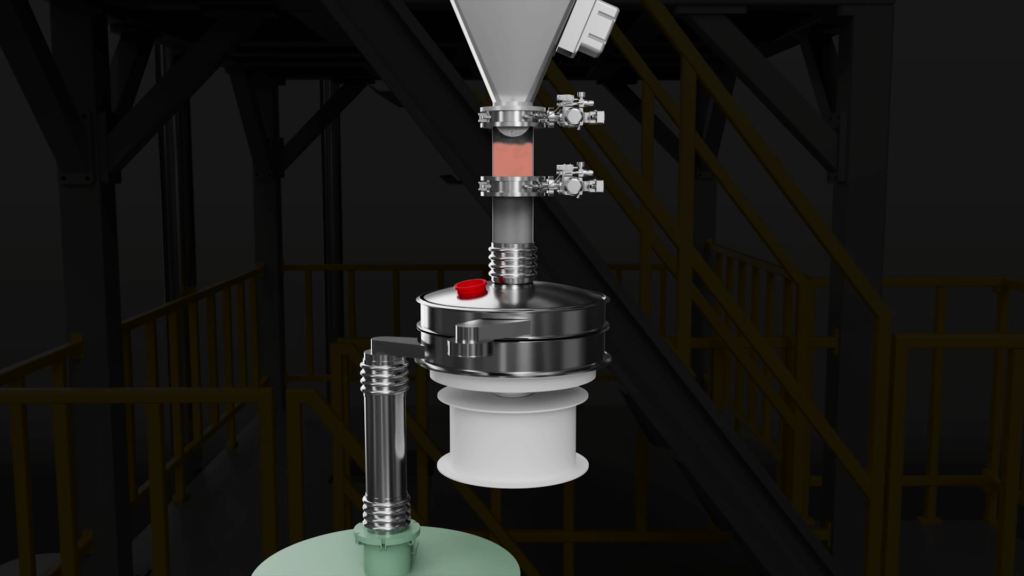

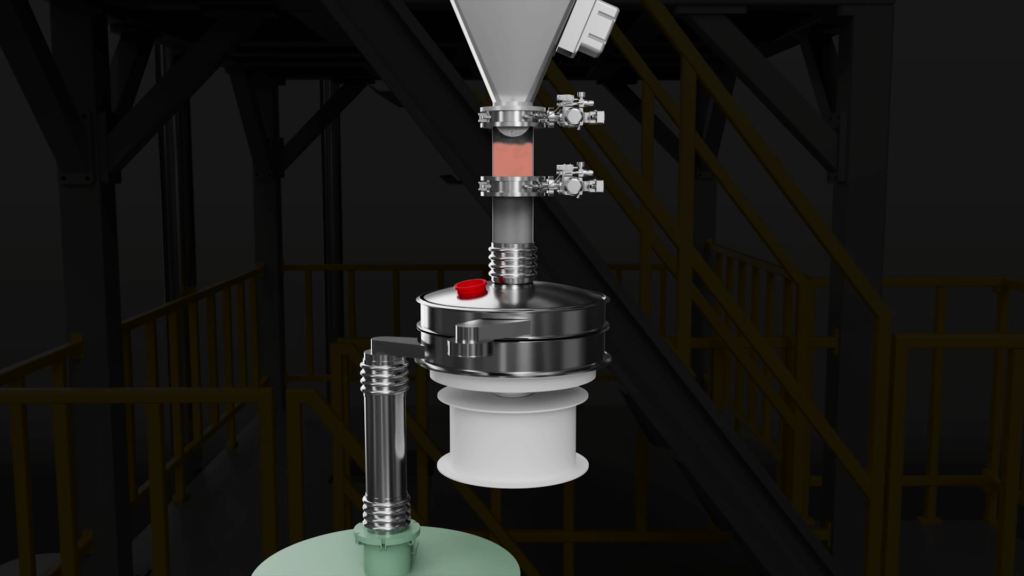

Feeder

Raw Material Screening Process

ㆍThe material dislodged from the bag filter is fed into the feeder

ㆍThe supersonic vibrations from the feeder finely shake the material,

allowing the sieving for particle separation

ㆍThe screened material then passes through a magnetic system

at the bottom, filtering out any remaining iron components

from the material

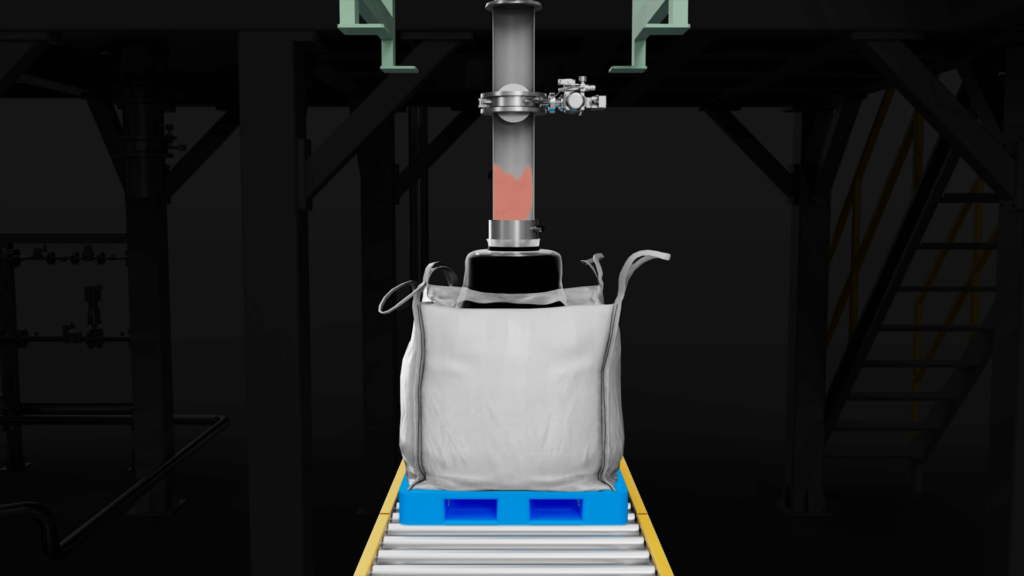

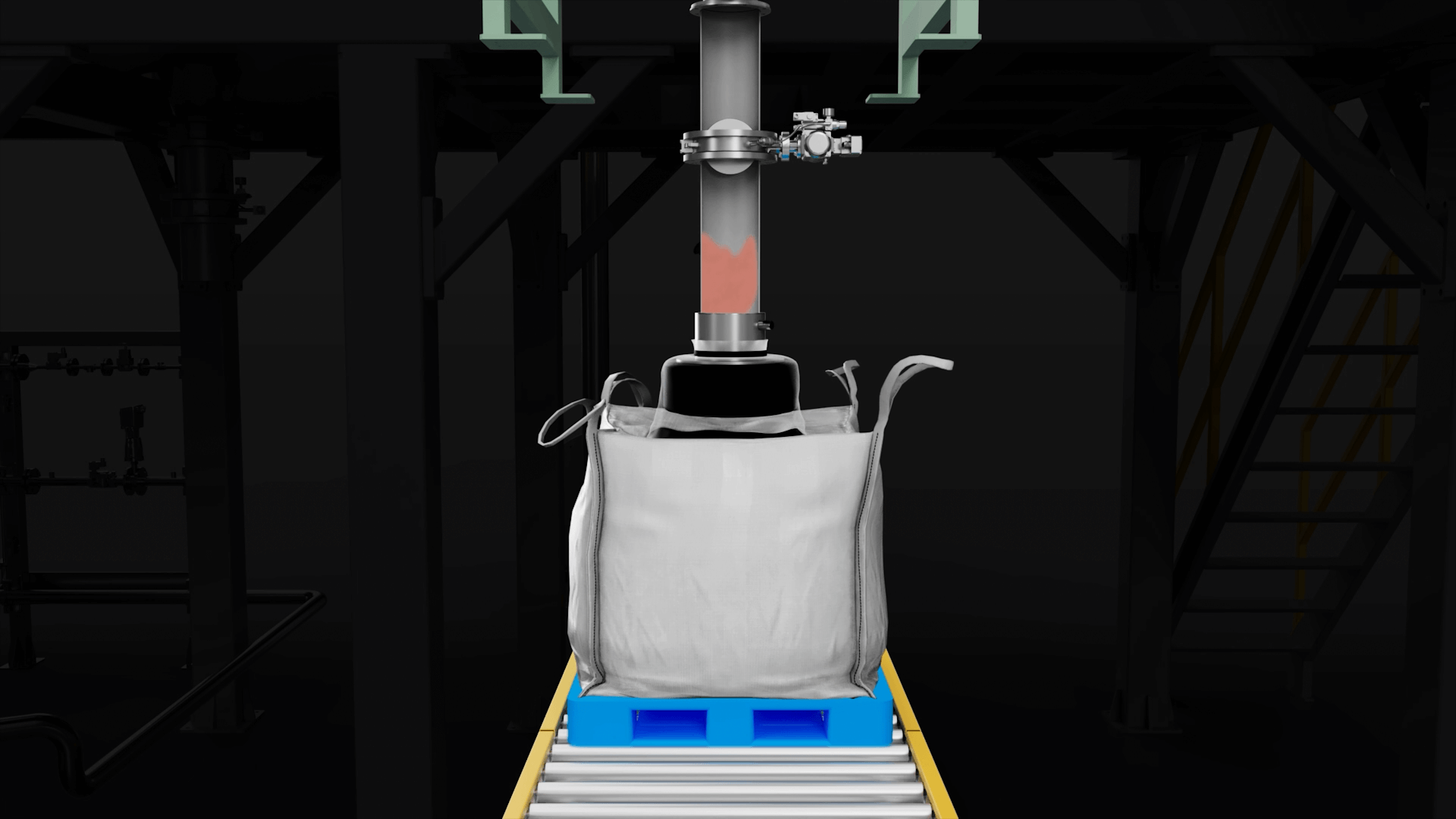

Final Raw

Material Transfer

ㆍThe fully ground final material is collected in one place,

completing the process

Final Raw

Material Transfer

ㆍThe fully ground final material is collected in

one place, completing the process

Milling Process of Air Jet Mill

Milling Process of Air Jet Mill

Raw Material Inlet

ㆍIntroduce the raw material

into the Air Jet Mill chamber

ㆍPowerful air jets are released

from three directional nozzles

to achieve the target

particle size grinding

ㆍDuring the primary milling,

large particles rise while

smaller particles are discharged

at the bottom

Cyclone

ㆍInside the cyclone, the airflow

spirals like a vortex

ㆍHeavy and large particles move

to the bottom, while smaller

particles follow the swirling

airflow to the top

Bag Filter

ㆍThe milled raw material follows

the airflow and adheres

to the surface of the bag filter

ㆍAir is momentarily released

from the upper nozzle

of the bag filter, dislodging

the adhered material on the filter

and directing it downward

Screening Process

ㆍThe material dislodged from

the bag filter is fed into the feeder

ㆍThe supersonic vibrations from

the feeder finely shake

the material, allowing the sieving

for particle separation

ㆍThe screened material then passes

through a magnetic system at the

bottom, filtering out any remaining

iron components from the material

Final Raw Material Transfer

ㆍThe fully ground final material is

collected in one place,

completing the process

Raw Material Inlet

ㆍIntroduce the raw materialinto the

Air Jet Mill chamber

ㆍFor the target particle size, powerful

air jetsare directed from three nozzles

ㆍDuring the first milling, large particles rise

while smaller particles are discharged

at the bottom

Cyclone

ㆍInside the cyclone, the airflow spiralslike

a vortex

ㆍHeavy and large particles move

to the bottom, while smaller particles follow

the swirling airflow to the top

Bag Filter

ㆍThe milled raw materialfollows

the airflowand is adsorbed onto

the surface of the bag filter

ㆍFrom the upper nozzle of the bag filter,

air is momentarily discharged, causing

the material on the filter to move to

the bottom

Raw Material Screening Process

ㆍThe material that falls from the bag filteris

introduced into the feeder

ㆍThe ultrasonic vibrationsfrom the feeder

finely shake the material, allowing the sieve

functionto filter the raw material

ㆍThe material that is then discharged is

passed through a magnetic systemat

the bottom of the equipment, removing

any iron contentfrom the material

Final Raw Material Transfer

ㆍThe final milled materialis gathered

in one place, completing the process

Applications

Secondary Battery

Materials

Chemistry

CNT Carbon

Black

Electronic

Coating

Ceramic

Powder/Glass

Powder

Nanoscience

and

Biomedicine

Metal Coating

Air Jet Mill Performance Requirements for the

Secondary Battery Milling Industry

Requirements

for the Secondary Battery

Milling Industry

Energy Transition for a Sustainable Future: Secondary Batteries

Particle Size Control

and safety of secondary

battery materials by precisely

controlling particle size

Increased Surface Area

through the process to enhance

chemical reactions and

electrochemical properties

Control

stability and electrical

conductivity of the battery

Production of High-Value-

Added Materials

of high-valueadded materials

by developing new materials

or mixtures

Process

Minimizing environmental impact

and maintaining productivity

through energyefficient processes

Various Materials

and material requirements

of secondary batteries

Particle Size Control

of secondary battery materials

by precisely controlling particle size

Increased Surface Area

through the process to enhance

chemical reactions

and electrochemical properties

Physical Property Control

and electrical conductivity of the battery

Value-Added Materials

of high-valueadded materials

by developing new materials

or mixtures

Process

and maintaining productivity

through energyefficient processes

Materials

and material requirements

of secondary batteries